5 Leading Factors Affecting Distribution Management

Why, regardless of industry, implementing the correct distribution strategy is critical to logistics effectiveness. How a company distributes its products to end users differs according to the sector, model, and final purpose. For some businesses, such as e-commerce merchants, selling directly to customers is the optimal approach. Other companies, such as wholesalers, may find that selling products through an intermediary is the best way to reach customers. However, regardless of how your items reach clients, implementing the proper formal distribution plan for your business can mean the difference between simply servicing your customers and offering an experience that will keep them coming again over time. Let’s take a look at some of the most important aspects that we’ve seen influence logistics planning and distribution management in the retail sector and beyond:

5 Factors Affecting Distribution Management

1. Distributor Point of View

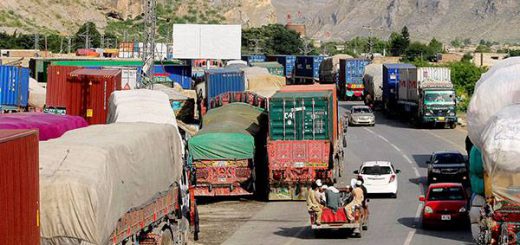

The ideal situation for distribution management would be for all fully loaded trucks to operate on regularly scheduled routes 100% of the time, with a 100% safety record and a 0% chance of severe weather occurrences occurring. Because customer purchases fluctuate in real life, obtaining this ideal goal is challenging. Temperature control and other particular handling can exacerbate the problem in some cases.

Furthermore, a successful distribution and warehousing organization works to maintain an optimal inventory with their suppliers to minimize inventory management expenses at a reasonable level while avoiding excessive safety stock. However, distribution management can effectively reduce these seemingly conflicting issues with adequate strategy and execution.

2. Interaction

The customer’s biggest nightmare is running out of merchandise or parts. Efficient distribution management requires the right flow of information, forecasting, and the provision of accurate, safe, and timely delivery.

In some cases, distributors are given real-time sales data electronically to replenish inventory immediately without the need for traditional ordering. This level of openness enables each link in the distribution chain to anticipate the needs of the end-user and change stock levels and delivery schedules accordingly. The customer will also supply continuous predictions in these circumstances.

In other circumstances, regular and open contact with the customer will assist the distributor in anticipating inventory replenishment and scheduling equipment and personnel for delivery.

3. Culture Development Through Planning and Measuring

The first stage in preparation is to create a customer-focused mission and company culture that balances the importance of customer happiness with commercial profitability realities. Forecasting, procurement, inbound freight management, warehousing, and inventory control are all measured, as are order processing, load consolidation, delivery schedules, and backhauls.

Look for methods to make each process more efficient while working directly with personnel in each discipline. Cycle time, cost analyses, on-time deliveries, precise order fulfillment, and safety measurements are all important factors. Create a strategy that includes contingencies for every situation. Also, it must ensure that all staff members contribute to making feasible plans.

Also Read:- What is Green Logistics and What Are Its Advantages?

4. Training and Commitment

Employee training to meet the needs of a distribution organization entails more than simply explaining and demonstrating “how” to perform a function. Underlying good performance is an awareness of “why” a job needs to be done correctly and the potential consequences of bad performance for the company’s future.

For an effective distribution management plan, implement the appropriate training and tools. The key to great distribution management is to assist new employees in becoming acquainted with all parts of the job. So that they can make educated and independent judgments in the future.

5. Using the Correct Tools: Warehousing and Distribution

Inventory management and warehouse management system (WMS) software can assist in optimizing warehouse space. Companies can avoid costly expansion by maximizing existing space and creating more efficient inventory placement.

Similarly, distributors can optimize vehicles and reduce costs by using loading and routing software. These tools combine load quantities and target arrival times with distance and drive time. A competent distribution management company’s fleet optimization is a significant cost driver.

Conclusion

Successful distribution management hinges on customer satisfaction while integrating all components effectively. It requires making well-informed decisions and continuously seeking to improve performance. Managers must skillfully coordinate various elements such as inventory, transportation, and warehousing to meet customer demands efficiently. By focusing on these aspects and consistently striving for excellence, businesses can optimize their distribution processes, leading to increased customer loyalty and overall operational success.

Recent Comments